SCREEN PRINTING

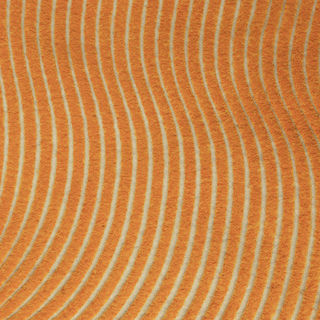

SPECIAL EFFECTS

3D – experiments – imagination

Color Effect

varies,

depending on the method

Feel

varies,

depending on the method

Durability varies

Organic-certified colors

possible

Color Options

CMYK ✔

Pantone/RAL/HKS ✔

NEON ✔

reflective ✔

phosphorescent ✔

metallic ✔

3D ✔

Suitable for

• Trade show clothing/Event wear

• Anniversary T-shirts

• Special occasions

• Festival & concert shirts

• Promotional textiles

• wedding apparel

File format

preferably vector files,

eps, ai, svg, pdf

From 25 pieces per motif

What’s possible?

In textile printing, especially screen printing, the possibilities are almost endless. We ourselves are constantly fascinated by what can be done. That's why Wednesday is our experiment day. Among other things, we test special additives and colors or experiment with pigments from natural materials, such as coffee grounds from roasteries, and print motifs with them.

Do you have ideas of your own but don't know if they are feasible?

Feel free to contact us!

Some really great things have already come out of our exchanges.

How it looks when printed